SMT Nozzle

Do you know about SMT nozzles?

Surface Mount Technology (SMT) is an essential production technique in the electronics industry. The effectiveness of an SMT assembly line depends on a number of parameters, with the nozzle being one of the most crucial.

A SMT nozzle is a tiny attachment that is mounted to the head of a pick-and-place SMT machine. It is responsible for picking up and positioning electronic components on the printed circuit board (PCB). The SMT nozzle is one of the most significant components of the SMT process since it impacts the assembly’s speed, precision, and quality.

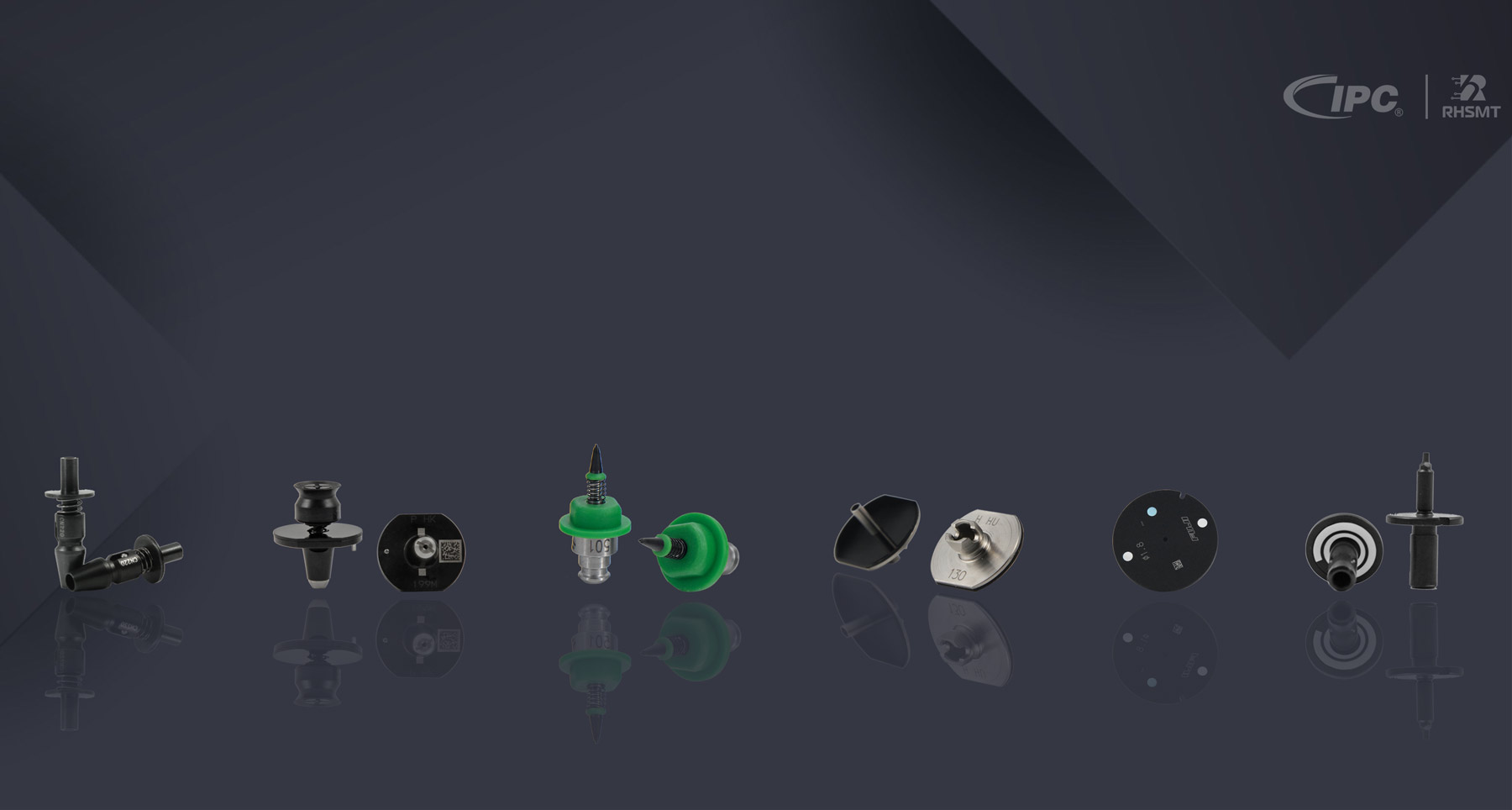

SMT nozzles are available in a variety of shapes, sizes, and materials, depending on the component being picked up and the pick-and-place machine’s parameters. Stainless steel, ceramics, and tungsten carbide are a few of the most prevalent materials utilized to create SMT nozzles.

The quality of the SMT nozzle is critical to the performance of the SMT assembly process as a whole. If the nozzle is of insufficient quality, it may lead to improper placement of components, component damage, or even machine failure. For this reason, it is essential to select a high-quality SMT nozzle that is built precisely for the components being used and the SMT machine’s specifications.

One of the most important characteristics of SMT nozzles is their capacity to handle a variety of components, including small passive components, BGA packages, and leaded devices. Additionally, SMT nozzles can be tailored to match the particular needs of an SMT assembly line. For instance, certain nozzles can be equipped with vision systems to improve the positioning precision of components.

SMT nozzles are crucial to the success of an SMT assembly line, in conclusion. To ensure the speed, accuracy, and quality of the SMT process, it is crucial to select the proper nozzle for the components being used and the machine’s parameters. Investing in superior SMT nozzles can improve the overall performance of the SMT assembly line and reduce the likelihood of machine faults and component damage.