A Yamaha feeder is an important part of an SMT machine. It sends parts to the pick-and-place machine so each part can be put on the PCB in the right spot. Even small feeding errors can slow work or cause defects, so a high-quality feeder is very important.

Yamaha feeders are known for smooth, stable, and accurate feeding. They help reduce machine stops, improve placement accuracy, and support both fast and flexible production.

Understanding SMT Feeders – How Yamaha Feeders Work

SMT feeders supply parts like resistors and ICs to the machine at the right time. If parts are not fed correctly, the machine cannot place them properly.

A Yamaha feeder moves the part tape smoothly and keeps each part in the correct position for pickup. This steady movement helps reduce errors and keeps the SMT line running well.

Types of Yamaha Feeders

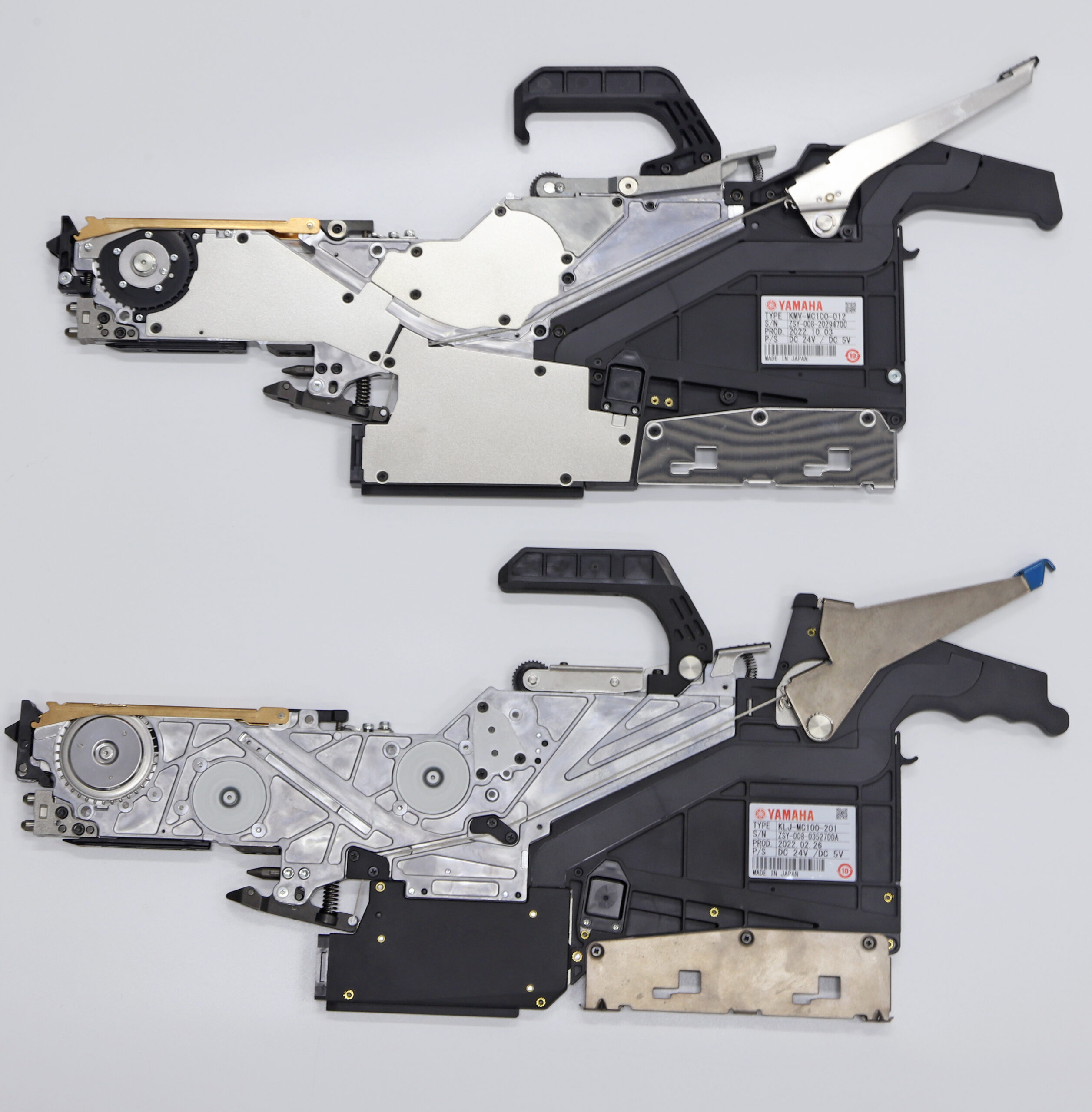

Yamaha Electric Feeders

These are the most common today. They use small motors to control movement. They provide highly accurate feeding and work well in fast and large-scale production. They produce less vibration and help maintain overall quality.

Yamaha Pneumatic Feeders

These feeders employ air pressure to move the tape. They are less expensive and simple in design. They are typically utilized in low- or medium-volume production. Electric feeders are more popular than pneumatic feeders, though pneumatic feeders are still useful for small budgets.

Yamaha Stick Feeders

These feeders handle components that come in tubes rather than tape. These are used for ICs or connectors that are not in the form of tapes. They are frequently used in small runs or prototype builds.

Key Features of Yamaha Feeder Systems

Auto-Loading Feeder (ALF)

This allows operators to add new parts even when the machine is in operation. It assists in decreasing machine interruptions and maintains the running of production.

Center-Open System

The center-open structure eliminates the necessity to peel off the top tape in setting it up. This reduces the possibility of mistakes that occur due to the presence of static electricity or fiber dust.

Compact and Lightweight Design

Yamaha feeders are slim and can be easily managed. Lifting and installation of most feeder carriages can be done with one hand, reducing setup time.

Quick-Change Carriages

Feeder carriages are easily changeable. This increases the speed of the product changeovers and also minimizes downtime between various PCB works.

Auto-Grouping and Setup Optimization

The inbuilt software packages cluster jobs and prevent unnecessary changeovers of products. This is particularly handy in high-mix production in which numerous PCB designs are put together.

Built-in Vision System

There are systems that check the nozzle tips using cameras as they operate. This helps identify missing, flipped, or incorrectly picked elements before they introduce defects.

Production Verification and Traceability

Barcode checks can be used to ensure the right parts are used during installation. It also captures the ID data, which will enable the manufacturers to monitor the parts that are used in each production batch.

Easy to Use Design

The features are also operator friendly like the tape guides which extend towards the user, and hence, components are loaded and set up faster and more conveniently.

Support for Many Component Types

Yamaha feeder systems are capable of working with varying component sizes, small chips and big parts. They also support various types of packing such as tapes, tubes, and trays.

Yamaha Feeder Compatibility with SMT Machine

The Yamaha feeders are designed in a manner that is compatible with Yamaha pick-and-place machines. Being designed to fit, they go together in timing and movement, hence easier to set up and more reliable.

The good fit also aids in the minimization of errors. This helps reduce mistakes and ensures that the machine runs continuously even at high speed. The right feeder should also be used to protect the machine and the PCB by avoiding improper layout of the parts and causing unnecessary tension to the equipment.

Applications of Yamaha Feeder in SMT Manufacturing

Yamaha feeders are very common in various industries such as-

- PCB assembly of consumer electronics.

- Electronics production of automotive.

- Industrial control systems

- Medical and communication equipment.

Yamaha feeders fit in various SMT settings, regardless of whether the production goal is speed, precision, or flexibility.

Benefits of Using Yamaha Feeder in PCB Assembly

The selection of appropriate feeders has a direct impact on the efficiency of manufacturing.

Major benefits include

- Reduced placement errors and higher yield.

- Fewer line stoppages and rework.

- Reduced time to change components.

- Long-term cost savings.

Simply put, a sound feeder maintains the rhythm of the whole SMT line- in other words, the rhythm of a drummer in a band.

How to Choose the Right Yamaha Feeder

The type of Yamaha feeder you select will depend on what your production line needs. To start with, consider the size of the components and the packaging. Some are in tape form and others are in tubes or trays. Thus, you require a feeder that can accommodate them well.

Then consider the amount of production you have each day. When your line is quick or produces a lot of boards, an electric feeder is the most common option as it feeds parts in a smooth manner and remains stable. Pneumatic or stick feeders can be used in smaller jobs or slow lines.

Ensure that the feeder fits your Yamaha pick-and-place machine. Feeding problems or placement errors may be caused by the wrong feeder.

The budget and maintenance cost are other issues you should consider. Electric feeders are initially more expensive, but they are often more durable and reliable, which can save time.

Electric Yamaha feeders tend to be preferable if you intend to expand your production or have the most stable performance.

Maintenance and Troubleshooting Tips

- Clean tape paths often

- Check moving parts

- Perform regular calibration

- Avoid warped or low-quality tapes.

Proper care extends the lifespan of the feeders and prevents unexpected troubles.

Yamaha Feeder vs Other SMT Feeders

Yamaha feeders also operate smoothly, even at high speed. They are user friendly, minimize errors during setups and also long lasting due to strong construction. All this makes Yamaha a reliable choice in the matters of correct and trouble-free feeding.

Buying Guide- Genuine vs Compatible Yamaha Feeders

Although compatible feeders might seem cheap, low quality copies can lead to alignment errors and machine damage.

Before purchasing

- Check the credibility of suppliers.

- Check performance certifications.

- Take into consideration long-term costs of operation.

- Manufacturers should invest in dependable feeders to maintain quality of production.

Conclusion

A Yamaha feeder is necessary to achieve stable and high-quality SMT production. It enhances precision, improves accuracy, reduces stoppages, and keeps the line running smoothly. You are assured of long-term value and high performance by purchasing them from a reliable supplier such as SMTfeeder.

Yamaha feeders are not simply a technical decision, but an intelligent investment in improved production.

Frequently Asked Questions

Q. What is the purpose of a Yamaha feeder?

It provides the parts to the SMT machine to be placed correctly.

Q. Can Yamaha feeders be interchanged?

Some are, but not all. It depends on the model of the machine.

Q. What is the life span of a Yamaha feeder?

If well maintained, they may serve a long time.

Q. What are the types of Yamaha feeders?

The feeder type can support numerous SMD components such as electric, pneumatic, and stick.