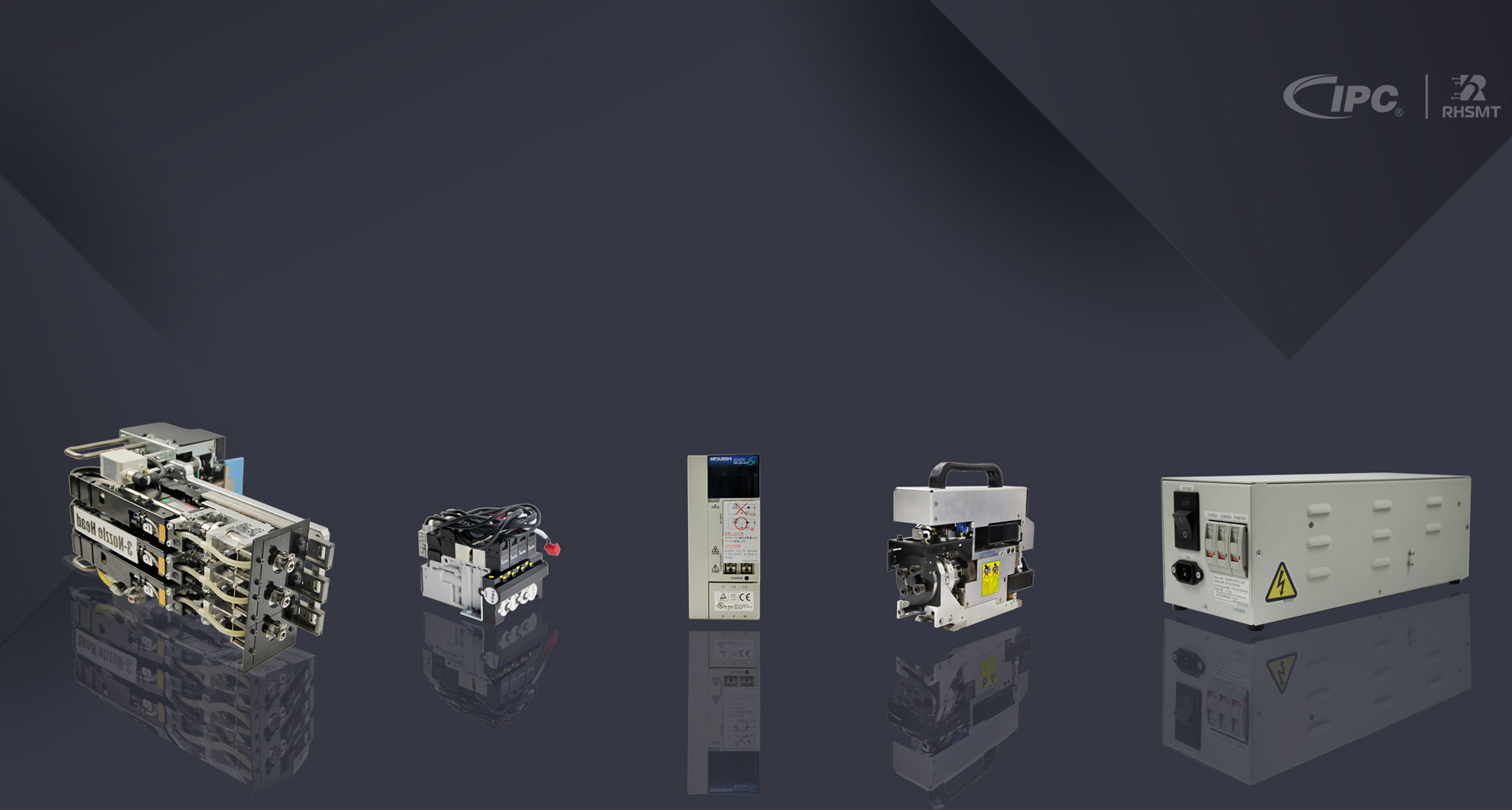

In the Surface Mount Technology (SMT) industry, automated production lines rely heavily on the availability of spare parts. Although these components often go unnoticed during daily operations, missing just one part can bring an entire line to a standstill.

Here’s why sourcing SMT spare parts can be more difficult than expected:

Equipment Changes Outpace Spare Part Support

SMT brands like Panasonic, FUJI, Yamaha, and JUKI regularly launch new machines, but they don’t always maintain long-term support for older models. When a manufacturer phases out a product line, spare parts for that model often become scarce. Many factories still run older machines and struggle to find genuine or even compatible parts.

Lead Times and Global Logistics Cause Delays

Most SMT spare parts come from Japan, China, or South Korea. Shipping internationally adds time — and customs, documentation, or export controls can slow things down even further. A part that’s technically “in stock” may still take weeks to reach a factory overseas.

Low Demand Doesn’t Justify High MOQs

Some factories only need one or two units of a specific part. However, many suppliers require minimum order quantities (MOQs) to justify production or shipping. This mismatch makes it hard for smaller buyers to access what they need when they need it.

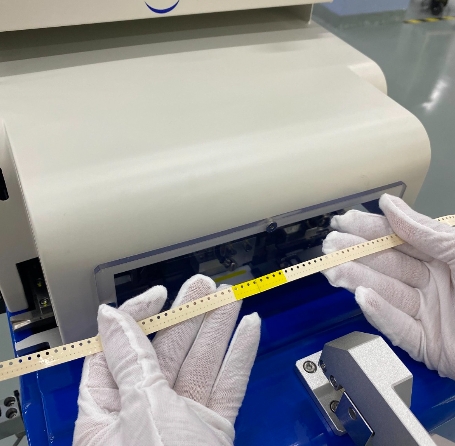

Compatibility and Quality Vary Widely

Not all third-party or “compatible” parts offer the same quality. Even small differences in nozzle diameter, feeder alignment, or sensor sensitivity can cause mounting errors or slow down the line. Choosing the wrong part affects both yield and reliability.

Confusing Part Numbers Lead to Mistakes

Many parts from different brands use similar-looking codes. Without clear documentation or technical support, it’s easy to order the wrong item. These errors waste time, money, and — most importantly — production uptime.

Sourcing SMT spare parts isn’t just a procurement task — it’s a key part of maintaining production stability. By understanding the typical pain points, SMT teams can prepare better, plan inventory more effectively, and avoid costly delays.

If your operation depends on machines from Panasonic, FUJI, Yamaha, or JUKI, it’s worth building relationships with suppliers who know these brands inside out and can provide reliable spare part support when it matters most.