SMT feeders are a very important part in the current electronics production industry. They are a significant component of Surface-Mount Technology (SMT), the technique of attaching small electronic parts to printed circuit boards (PCBs).

The ability to select the appropriate SMT feeder may greatly impact the performance, as it will assist in accelerating the manufacturing process, reducing the number of errors, and increasing common product exceptional.

What is an SMT Feeder?

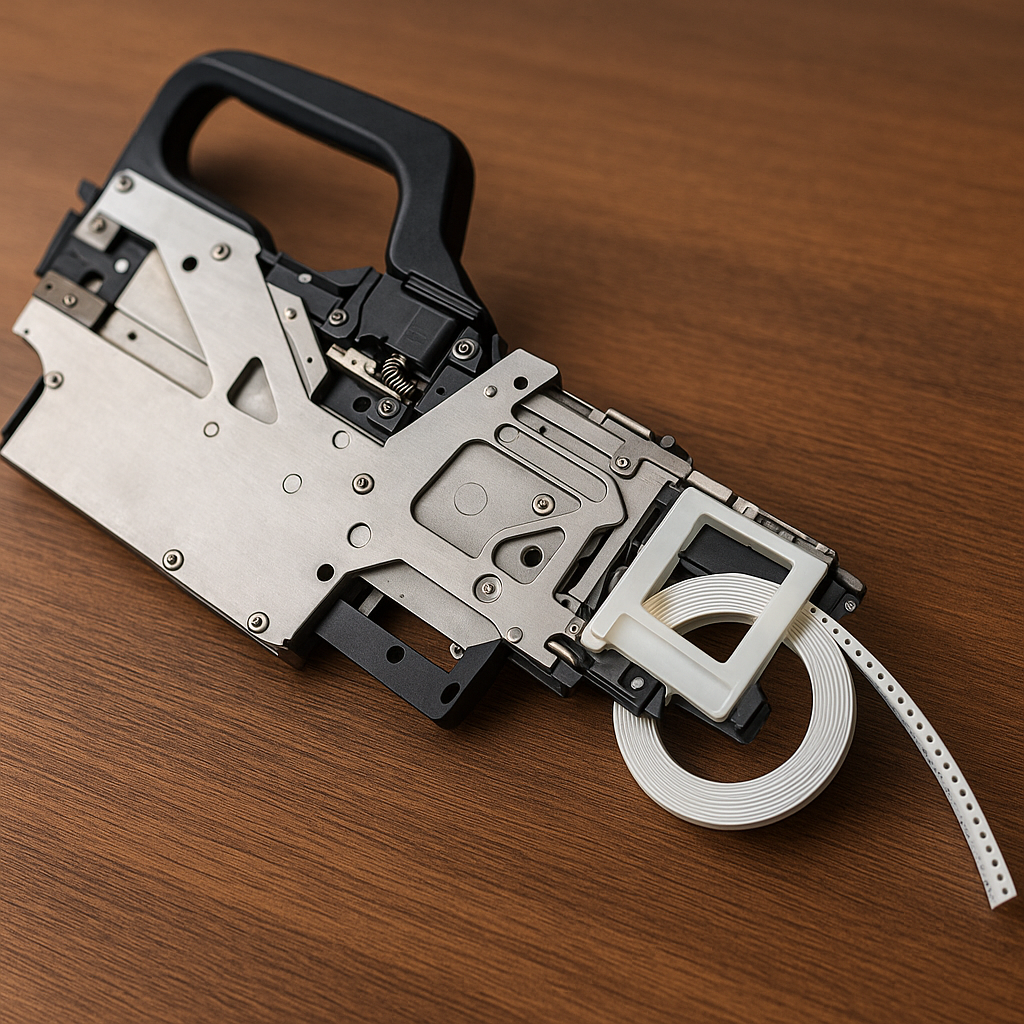

A tool that automatically feeds electronic components to a pick-and-place machine when assembling a PCB is known as an SMT feeder. It is basically meant to ensure that every part is supplied to the machine in a fast, precise, and effective manner.

Main Types of SMT Feeders

- Tape Feeders – The most widespread, and are used to feed components off a reel of tape.

- Tray Feeders – These are ideal where components of large size or delicate in nature cannot be supplied on tape.

- Stick Feeders – This is designed to accommodate smaller or shaped parts that can be found in the stick shape.

SMT feeders operate in tandem with pick and place machines, where every part is found in the circuit board at the right location and at the right time in the assembly.

The Benefits of SMT Feeders include the following-

SMT feeders increase the efficiency, accuracy and reliability of modern day electronic manufacturing. The key advantages they have are as follows-

Better Production Effectiveness.

The SMT feeders assist in accelerating the production process by automatically feeding the machine with parts. This saves manual labor and decreases the downtimes, and the assembly line continues running well. Due to this, the products are manufactured with increased speed and efficiency.

Increased Accuracy and Precision.

In PCB assembly, it is very crucial to place every part in the correct location. The SMT feeders ensure that all the parts are deposited at the right location, avoiding errors such as inaccurate location or placement. This enhances quality and saves the cost of making corrections in the future.

Cost-Effectiveness

Although SMT feeders may be more expensive in the short run, they are more economical in the long run because of the reduction of labor expenses and a decrease in waste. Automation saves manual error as well as enhancing productivity, thus manufacturing is cost-effective in the long-term.

Adaptability and Interchangeability.

SMT feeders today are able to work with a variety of parts types and sizes. They are compatible with other machines and can be reconfigured easily when switching to products or designing a new product. This simplifies the production and time saved on setting up.

Consistency and Minimum inaccuracies.

SMT feeders eliminate the possibility of human error since they are automated. They are capable of operating long hours without any reduction of performance and hence maintain stable quality, reduce stoppages and wastes.

Favors Automation and Industry 4.0.

Smart factory systems are able to be linked with new SMT feeders. They can enable real-time tracking, early problem detection as well as data analysis to enhance planning and efficiency. This is to assist factories in working at a quicker pace.

Common Uses of SMT Feeders

Many industries are in need of fast and accurate electronic assembly; these industries utilize SMT feeders. Some of the primary areas where they are utilized are listed below-

- Electronics manufacturing – The tools are essential in PCB manufacturing, assisting in the placement of parts at a fast rate, and they are precise when it comes to the placement of parts during the assembly.

- Automotive Electronics – SMT feeders were employed to assemble sensors, control units and safety systems that should be of high standard reliability.

- Consumer Electronics – These are significant in the creation of products such as smartphones, computer, tablet and smart home products where speed and accuracy are critical.

- Medical and Aerospace Devices – These sectors use SMT feeders to perform high accuracy assembly processes in which safety, accuracy, and reliability are paramount.

Considerations when Selecting SMT Feeders.

To choose an SMT feeder, there are several important points to consider to be sure that it can meet your production needs.

- Part Type and Size – Your feeder should have the capability to deal with each of the various component types and sizes that you utilize in your production line.

- Production Speed – Select a feeder that fits your assembly line speed so that your workflow is easy and efficient.

- Machine Compatibility – Ensure that the feeder is compatible with your pick-and-place machines so that they can be easily set up and are reliable to use.

- Maintenance Requirement – Select feeders that are easy to clean and maintain. This assists in making sure that you minimize the time down and your production is not lagging.

- Cost vs. Output – consider both the cost and long term performance. A minor increase in investment may be justified as long as it offers increased efficiency and reliability in the long run.

Working with a trusted SMT Feeders supplier ensures you get consistent quality, reliable delivery, and expert technical support.

Tips for the Best Out of SMT Feeders.

To ensure your SMT feeders run well and have increased longevity, take into consideration the following simple tips:

Clean and Check Feeds- Clean your feeders regularly to get dust, dirt or small particles off them. Frequent washing can avoid feeding difficulties and maintain the correct functioning of the machine.

Load Parts Carefully – It is important to make sure that when loading parts the tape or tray is loaded in the correct position. By being in position, feeding is easy and makes jams and misdeeds avoided.

Install Quality Feeders – It is worth spending money on good quality feeders. They are also better, longer lasting, and the breakdowns are minimized, and time and repair are saved.

Train Your Staff – It is important to ensure that the staff that will be dealing with the feeders is properly trained on how to maintain and handle them. The experienced operators are able to identify minor problems before the production line is brought to a stop.

Conclusion

An important component of PCB assembly today is SMT feeders. They assist in enhancing speed, accuracy, and the quality of production in general and minimizing waste and downtime.

To any electronics producer, the selection of the suitable SMT feeder and supplier can be considered a significant step in the right direction during streamlined operations, improved product quality, and success in the long run.

Partnering with a leading SMT Feeders manufacturer helps you achieve higher productivity and long-term cost efficiency.

FAQs

Q1. What is the principal benefit of SMT feeders?

They also produce at a quicker and more precise rate by automatically loading the machine with components.

Q2. What are the benefits of SMT feeders to PCB assembly?

They also give speed in delivery parts and minimize manual labour, which keeps the production running smoothly and efficiently.

Q3. Are SMT feeders capable of loading any parts?

Yes. SMT feeders are capable of feeding a large variety of shapes and sizes of components depending on the model.

Q4. Do SMT feeders work well in small scale production?

Yes. The fact that production is quick, fewer mistakes are made, and consistency is improved even in small operations.

Q5. What are the maintenance requirements of SMT feeders?

Do clean them frequently, and look at their being in place, and keep them always well-adjusted to do their work truly.