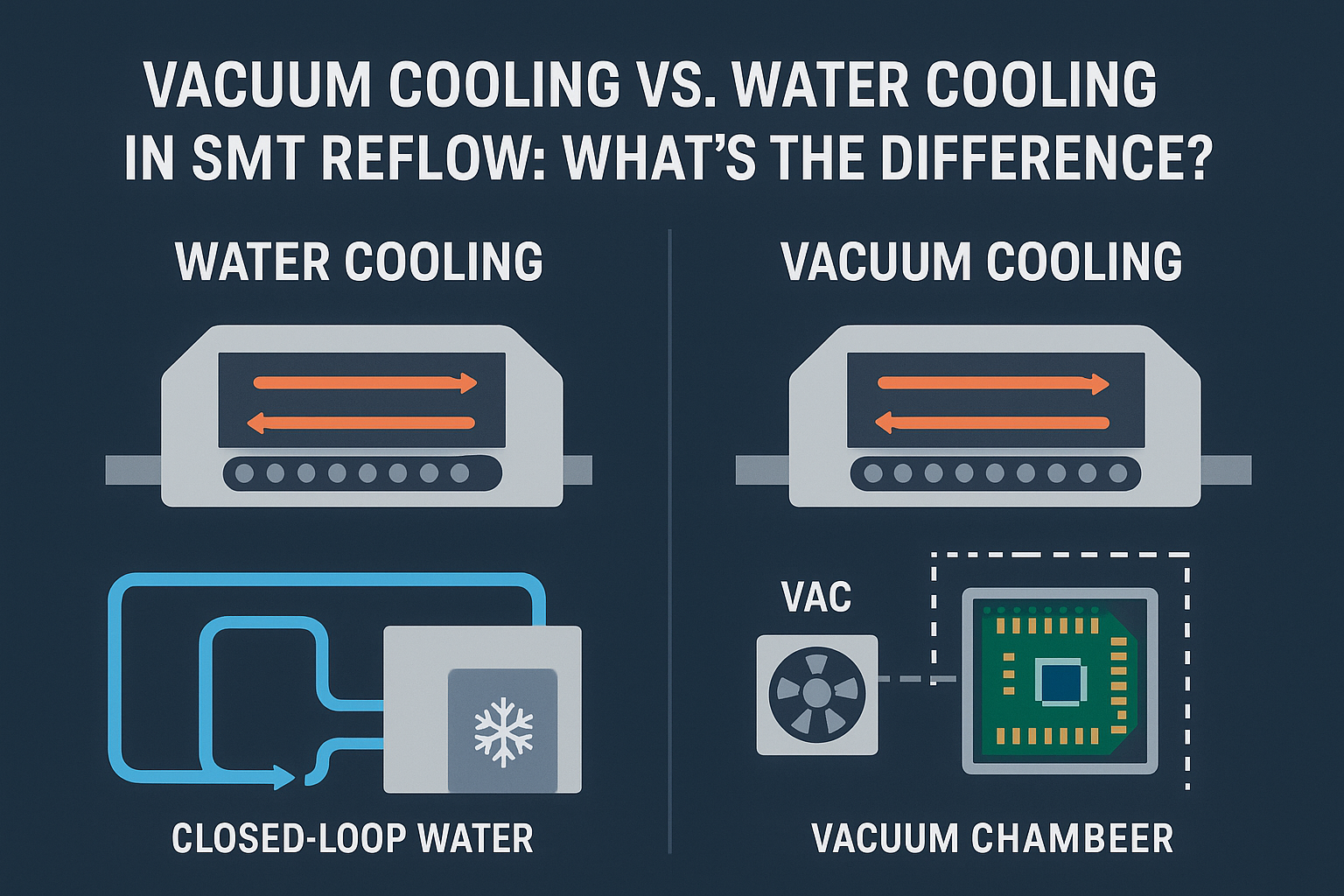

In modern SMT production, temperature control plays a key role in ensuring stable solder joints and high overall line efficiency. While convection heating receives most of the attention in a reflow oven, the cooling process is just as critical. Today, two cooling methods are commonly used in advanced SMT reflow systems: vacuum cooling and water cooling.

This article explains how they work, their differences, and when each method is most suitable.

1. What Is Water Cooling in Reflow?

Water cooling is the mainstream solution in most mid-to-high-end reflow ovens.

A closed-loop water circulation system absorbs heat from the cooling zones and transfers it away through a heat exchanger. This allows the oven to quickly reduce the PCB temperature after reflow.

Key characteristics

- Uses a water chiller and closed-loop piping system

- High cooling efficiency for large-scale production

- Stable cooling rate, suitable for most PCB types

- Lower initial cost and easier maintenance compared to vacuum systems

Common applications

- Standard consumer electronics

- Industrial control boards

- Automotive electronics not requiring ultra-low voids

2. What Is Vacuum Cooling in Reflow?

Vacuum cooling, often integrated with a vacuum reflow system, reduces the pressure around the PCB during solder solidification.

By creating a low-pressure environment, trapped gases in the solder joint are removed, effectively reducing solder voids.

Key characteristics

- Removes air from solder joints during cooling

- Significantly reduces void rates (often <5%)

- Requires a vacuum chamber + cooling module

- Higher equipment and maintenance cost

Common applications

- High-reliability PCBs

- Power electronics (IGBT, MOSFET, SiC modules)

- Automotive components requiring <10% voids

- Medical/defense electronics

3. Core Differences: Vacuum Cooling vs. Water Cooling

| Feature | Water Cooling | Vacuum Cooling |

|---|---|---|

| Primary Purpose | Fast temperature reduction | Void removal + controlled cooling |

| Cooling Speed | High | Medium (depends on vacuum cycle) |

| Solder Joint Quality | Standard | Ultra-low void, high reliability |

| Equipment Cost | Lower | Higher |

| System Complexity | Moderate | High (vacuum chamber, seals, pumps) |

| Best for | General SMT products | Power devices, automotive, high-reliability assemblies |

4. Which Cooling Method Should You Choose?

If your products focus on general electronics and priority is cost-performance, water cooling is more than sufficient.

If you are manufacturing high-power devices or automotive electronics, and void standards are strict, vacuum cooling provides a clear advantage by enhancing solder reliability.

In many factories, both systems coexist:

- Standard lines → water-cooling reflow

- Special high-reliability lines → vacuum reflow with vacuum cooling

Conclusion

Water cooling is efficient, stable, and suitable for most SMT applications.

Vacuum cooling, on the other hand, offers superior solder joint quality by significantly reducing voids, making it essential for high-reliability electronics.

Choosing the right cooling method depends on product requirements, void specifications, and production cost considerations.